Coal tar s unique molecular structure provides a system that resists water and vapor penetration insect damage chemical attack uv exposure and most elements considered common enemies to other roof membrane systems.

Coal tar pitch roofing details.

Coal tar pitch is melted on site in an industrial kettle and applied to the roof as a hot liquid.

Construction definition coal tar pitch roofing.

Coal tar pitch roofing in the processing of coal to make coke for steel making volatile compounds are collected from the coking ovens condensed and separated and become the base of hundreds of raw materials including dyes plastics and a byproduct called coal tar pitch.

History of coal tar roof systems a waterproofing material used since the beginning of time coal tar pitch is a superior and sustainable raw material that is ideal for use within a roofing membrane system.

It is solid for all practical purposes at room temperature.

Coal tar coatings are made from processed coal tar pitch dissolved in suitable petroleum solvents.

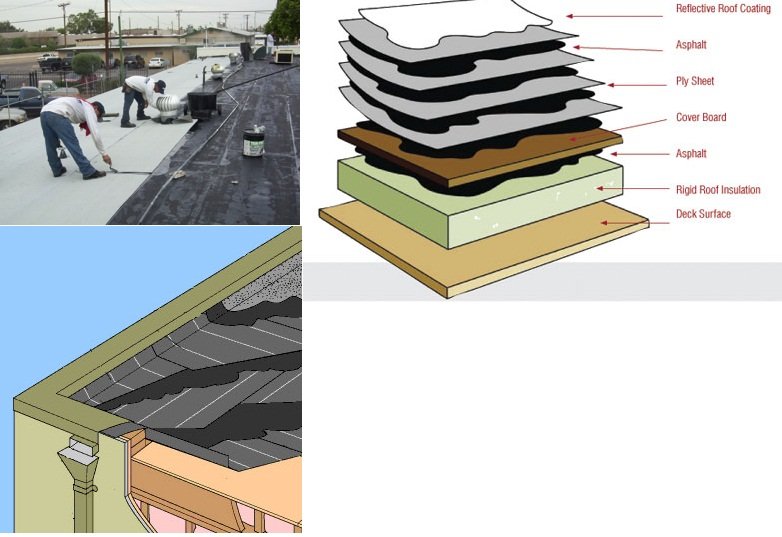

Built up roofing in which coal tar pitch forms the waterproofing component of the roof membrane.

Coal tar films provide very good corrosion protection.

Coal tar pitch is produced by distilling or heat treating coal tar which is a by product of the production of coke or coal gas.

Coal tar pitch was a by product of processing coal to make coke which in turn was used in making carbon steel and electrodes for the aluminum industry.

Bituminous roofing hits the market back in the pre world war ii years there were two bituminous substances bitumens that dominated the roofing industry.